Curtain Wall

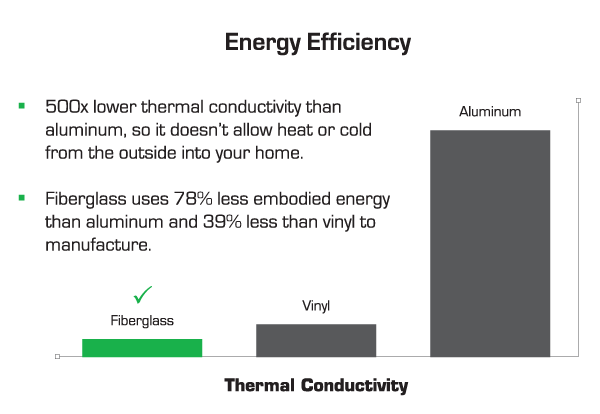

Energy Efficiency

Energy efficient frames have low conductivity that discourages the transfer of cold into a building. Fiberglass has a much lower conductivity than metal options; specifically, 500 times less conductive than aluminum.

Eco-Friendly

Due to its energy performance and longevity, fiberglass is often selected for Net Zero and LEED projects.

Greener Building with Composite

With an industry-wide focus on budgets and operating costs, not to mention more stringent building codes and LEED rating on the horizon, building with conventional aluminum curtain wall can be a hard choice to justify.

Compared to a conventional Kawneer 7500 aluminum system, GlasCurtain fiberglass system achieves:

- Tactile warmth

- 5-10% energy savings.

- Similar cost to aluminum framing

- 35% less thermal bridging.

- Reduced expansion and contraction.

- Excellent strength with further reinforcing available.

- More LEED v4 points.

- 40% less embodied energy as per Athena Sustainable Materials Institute LCA.

- 60% less GHGs, meeting the Architecture 2030 Challenge.

Studies have shown a strong preference for the fiberglass over the aluminum. Across each indicator measured, fiberglass profiles demonstrate a lower cradle-to-grate environmental impact. Fiberglass results are between 40% to 90% of aluminum environmental burden results.

While manufacturer’s try to off-set this impact by pointing to end of life recycling, in a typical building demolition, a lot of this material ends up in a landfill anyhow.

Fiberglass framing offers a far more environmentally friendly build than aluminum, with comparable strength, longevity and a much lower thermal conductivity.